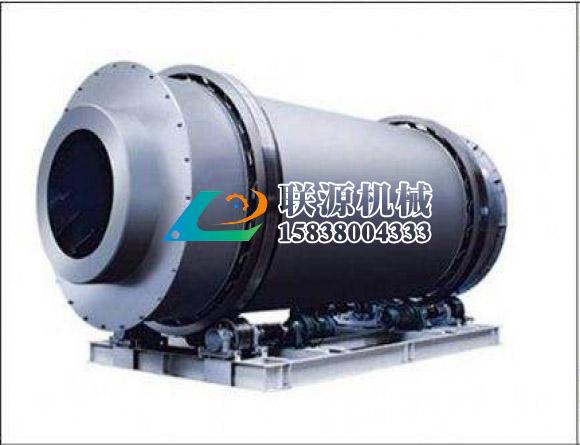

The overall structure of the three-drum sand dryer is composed of three interlocking cones welded in different directions and sequences. This special structure determines the size of its output, so this new type of dryer is also called a three-pass dryer.

1. The equipment investment is 20% of that of imported products. It is made of wear-resistant manganese plate, which is 3-4 times more wear-resistant thanordinary steel plate.

2. The initial moisture content of the material is 15%, and the final moisture content is guaranteed to be below 0.5-1%. It is a drying engineering product for cement plant slag powder, dry mortar production line, etc.

3. The thermal efficiency is increased by more than 40% compared with the traditional single-drum dryer.

4. The fuel can be white coal, bituminous coal, coal gangue, oil, and steam. It can dry blocks, granules, and powdered materials below 20-40mm.

5. The floor space is reduced by about 60% compared with the single-drum dryer. The civil engineering investment is reduced by about 60%, and the installation is convenient.

The materials to be dried in the dryer enter the cylinder from the feed box and the feed slide, and are then pushed to the rear end by the spiral lifting plate. Since the dryer is placed at an angle, the materials flow to the rear end

under the action of gravity and rotation, and on the other hand, the materials are repeatedly lifted up by the lifting plate, brought to the upper end and then continuously scattered down, so that the materials form a uniform curtain in the cylinder, fully exchanging heat with the hot air flow in the cylinder. Due to the repeated scattering of the materials, the moisture contained in them is gradually dried, thereby achieving the purpose of drying.

Main structure: It mainly consists of the frame part, the eccentric shaft rotating part, the crushing chamber working part, the safety device, the discharge port adjustment device and other parts.

Specifications (m) (diameter x length) | Cylinder volume (m³) | Production capacity (t/h) | Installation slope (%) | Higher intake air temperature (℃) | Main motor (kw) | Total weight (t) |

Φ1.2×8.0 | 9.0 | 1.9-2.4 | 3-5 | 700-800 | 7.5 | 9 |

Φ1.2×10 | 11.3 | 2.4-3.0 | 3-5 | 700-800 | 7.5 | 11 |

Φ1.5×12 | 21.2 | 4.5-5.7 | 3-5 | 700-800 | 15 | 18.5 |

Φ1.5×14 | 24.7 | 5.3-6.6 | 3-5 | 700-800 | 15 | 19.7 |

Φ1.5×15 | 26.5 | 5.7-7.1 | 3-5 | 700-800 | 15 | 20.5 |

Φ1.8×12 | 30.5 | 6.5-8.1 | 3-5 | 700-800 | 18.5 | 21.5 |

Φ1.8×14 | 35.6 | 7.6-9.5 | 3-5 | 700-800 | 18.5 | 23 |

Φ2.2×12 | 45.6 | 9.7-12.2 | 3-5 | 700-800 | 22 | 33.5 |

Φ2.2×14 | 53.2 | 11.4-14.2 | 3-5 | 700-800 | 22 | 36 |

Φ2.2×16 | 60.8 | 13.0-16.2 | 3-5 | 700-800 | 22 | 38 |

Φ2.4×14 | 63.3 | 13.5-16.9 | 3-5 | 700-800 | 37 | 45 |

Φ2.4×18 | 81.4 | 17.4-21.7 | 3-5 | 700-800 | 37 | 49 |

Φ2.4×20 | 90.4 | 19.3-24.1 | 3-5 | 700-800 | 45 | 54 |

Φ2.4×22 | 99.5 | 21.2-26.5 | 3-5 | 700-800 | 45 | 58 |

Φ2.6×24 | 127.4 | 27.2-34.0 | 3-5 | 700-800 | 55 | 73 |

Φ3.0×20 | 141.3 | 30.1-37.7 | 3-5 | 700-800 | 75 | 85 |

Φ3.0×25 | 176.6 | 37.7-47.1 | 3-5 | 700-800 | 75 | 95 |

Φ3.2×25 | 201 | 42.9-53.6 | 3-5 | 700-800 | 90 | 110 |

Φ3.6×28 | 285 | 60.8-76.0 | 3-5 | 700-800 | 160 | 135 |